Qualify for ISO 26262, DO-178B/C, IEC-61508

Comprehensive qualification support for safety-critical standards

We offer Qualification Support Kits (QSKs) that help you simplify and automate your qualification process. These kits are especially popular with our customers in the automotive and avionics industries.

Safety Standards We Support

Our tools are qualified for the most demanding safety-critical standards across automotive, aerospace, and industrial domains.

ISO 26262

Automotive functional safety standard

Up to ASIL D

DO-178B/C

Avionics software development standard

Up to DAL A

IEC 61508

Industrial functional safety standard

Up to SIL 4

Each QSK consists of the following parts:

- specification of the tool functional requirements

- test cases and test procedures

- requirements trace data (traceability matrix)

- test suite and execution framework

- tool lifecycle data

Tool functional requirements (TOR)

This part defines the tool functions and technical features which are stated as requirements to the tool behavior under normal operating conditions, and specifies the operational context and conditions in which the tool computes valid results, i.e. restrictions such as not supported hardware options or specific code constructs.

Test cases and procedures (TOVVCP)

The test cases demonstrate the correct functioning of all specified functional requirements. Test case definitions include the overall test setup and a detailed structural and functional description of each test case, i.e. how it works and what the expected result is.

Trace data (traceability matrix)

Each functional requirement and each test case is assigned a unique identifier, enabling a mapping to be realized over the so-called traceability matrix.

Test suite and execution framework

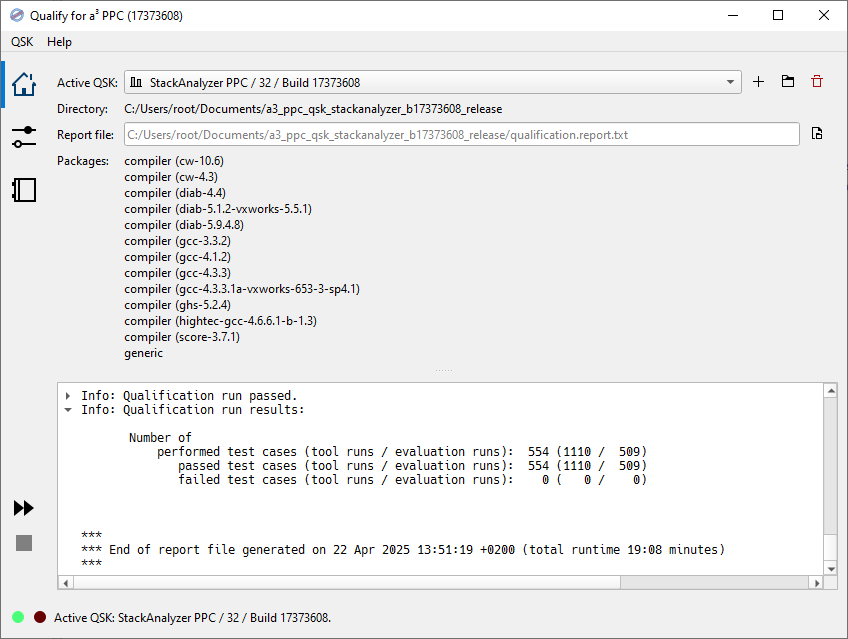

The test suite contains implementations of the test cases specified in the TOVVCP that are designed to show that the requirements described in the TOR are satisfied. Each test case consists of one or several tool test runs and optionally, evaluation test runs. The output of test case execution constitutes the tool verification results. If all test cases pass, compliance with the TOR has been demonstrated.o.

Tool lifecycle data (QSLCD)

In addition to demonstrating that the tool operates correctly in the operation context of its user, safety standards often require evidence that the tool development process fulfills certain demands, e.g. with respect to quality assurance, traceability, requirement engineering and verification activities.

These topics are covered by documents which detail the tool development processes at AbsInt:

- Software Development Plan

- Software Configuration Management Plan

- Software Quality Assurance Plan

- Software Quality Assurance Records

- Software Verification Plan

- Software Verification Results

- • Compliance Certificate

Easy to use

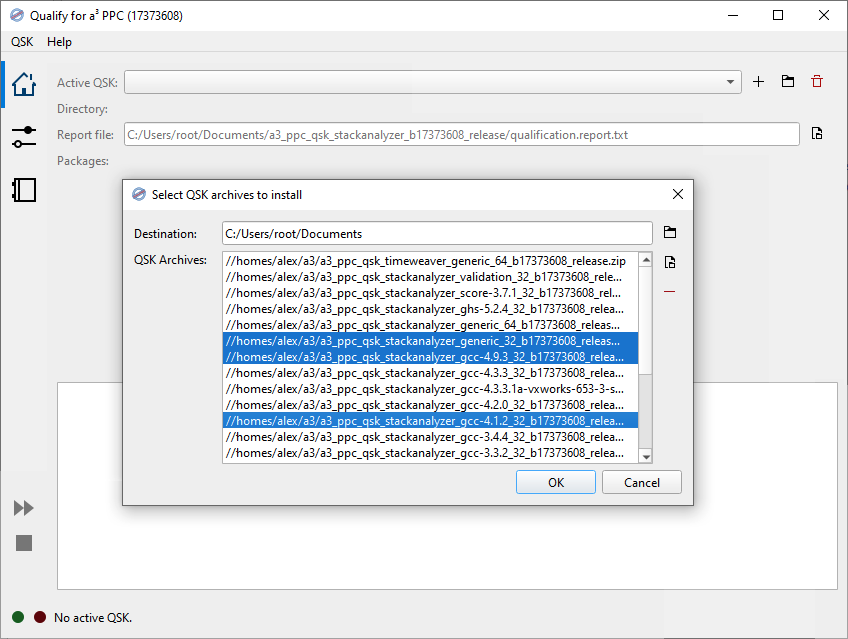

Each QSK is delivered as a single ZIP archive that doesn’t need to be unpacked. You can run one or several QSKs directly from within the GUI, or from the command line. All tests are carried out fully automatically, and the results are then displayed and/or saved to a report file specified by you. The qualification results can be printed and attached to your certification documents.

Qualification Benefits

- Reduce certification effort

- Pre-qualified tool evidence

- Expert qualification support

- Comprehensive documentation

- Proven track record

What's Included

Tool Qualification Document

- Comprehensive TQD covering all aspects

Safety Manual

- Detailed safety and usage guidelines

Certification Evidence

- Pre-compiled evidence packages

Qualification Process

Assessment

Evaluate your project requirements and applicable standards

Planning

Develop qualification plan tailored to your needs

Execution

Implement qualification activities and documentation

Certification

Support certification activities with authorities.

Industry Applications

Automotive

ISO 26262 compliance for ADAS, powertrain, and chassis systems

- • ASIL B, C, D applications

- • ECU software development

- • Tool chain qualification

Aerospace

DO-178B/C certification for avionics software

- • DAL A through E

- • Flight critical systems

- • Tool qualification data

Industrial

IEC 61508 compliance for process safety systems

- • SIL 1-4 applications

- • Process control systems

- • Safety instrumented systems

Ready for Safety Certification?

Let our qualification experts help you achieve compliance with safety standards