Availability Workbench

Availability Workbench

Powerful simulation software for improving asset performance. Maintenance and spares optimization, availability studies, reliability centered maintenance, life cycle cost evaluations and accelerated life testing all in one integrated suite.

• Connect directly to your SAP or MAXIMO system and analyze your data

• Identify critical equipment

• Automatically build failure models using Weibull analysis

• Optimize your maintenance plans using simulation and reduce costs

• Predict system availability and optimize your design

• Simulation of multiple-product capacity with target cost penalties

• Model system dependencies with RBDs or fault trees

• Build in operational rules for accurate performance simulation

• Determine the most effective spares holding policy

• Predict life cycle costs

• Analyze your test data for stressed failures in the ALT module

• Identify plant performance trends in the Process Reliability module

Our software has been in continuous development since the 1980s and is the recognized standard for safety and reliability professionals.

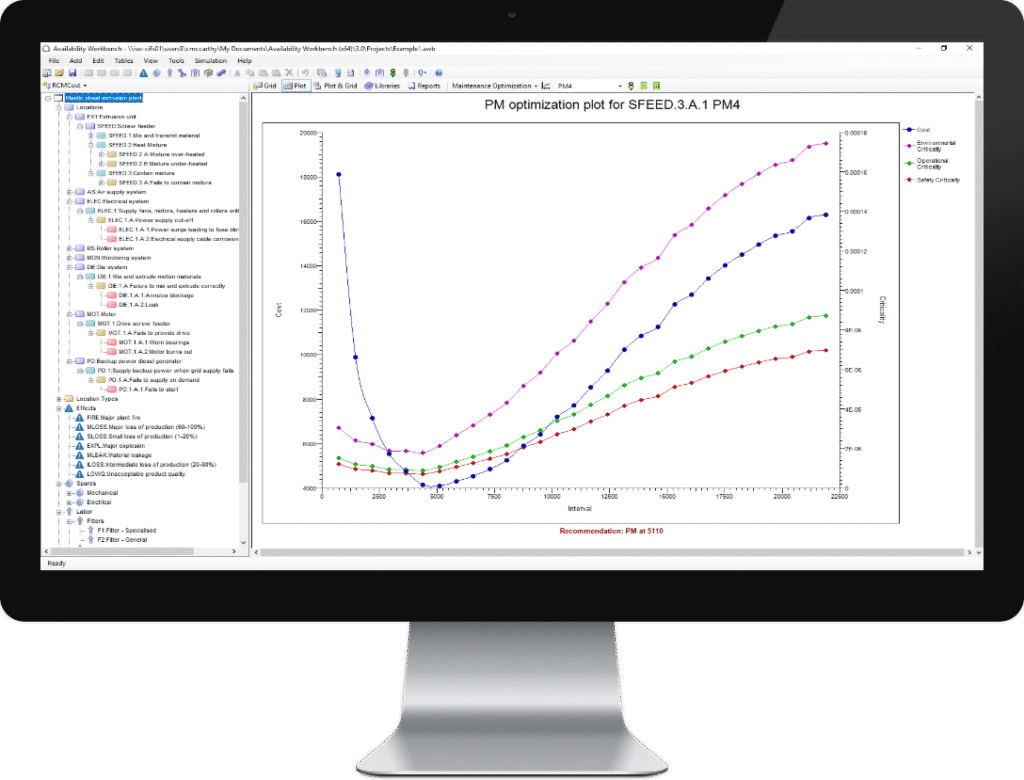

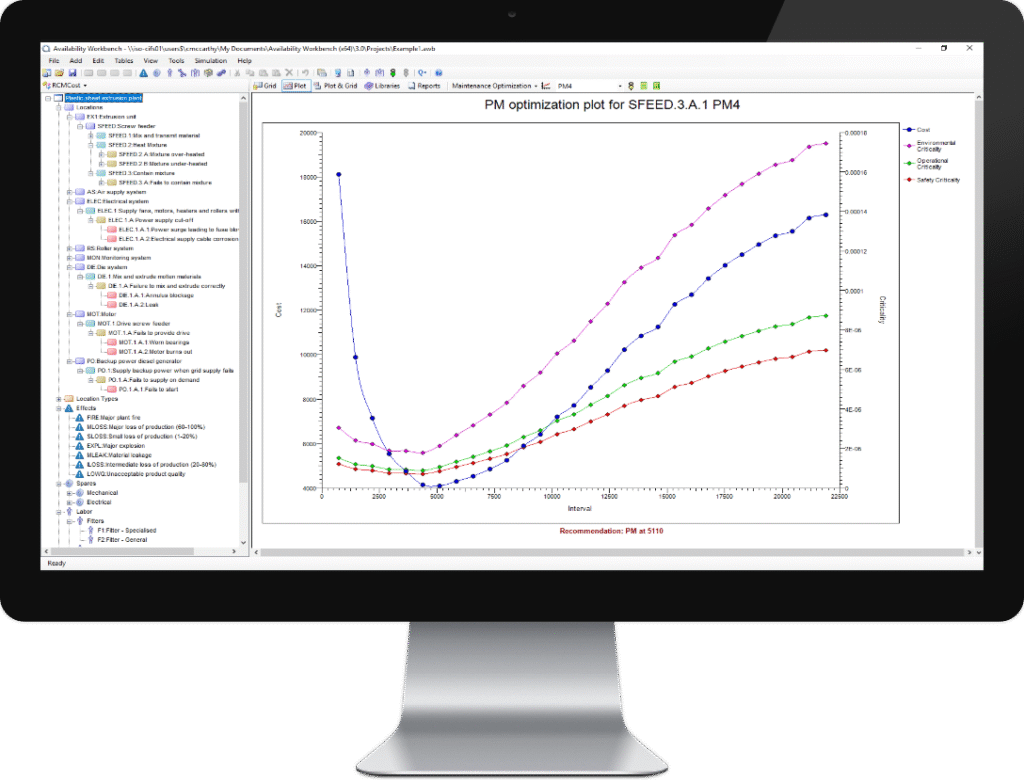

Reliability Centered Maintenance Software

Availability Workbench and dive into our powerful RCMCost module.

- Predict asset performance

- Optimize your maintenance strategy

- Reduce operational risks

- Improve profitability

- Increase uptime and lower costs

- Optimize spares holdings

- Simulate predictive maintenance

- Meet safety, environmental and operational targets

- Supports standards such as SAE JA1011, MSG-3 and

MIL-STD-2173(AS)

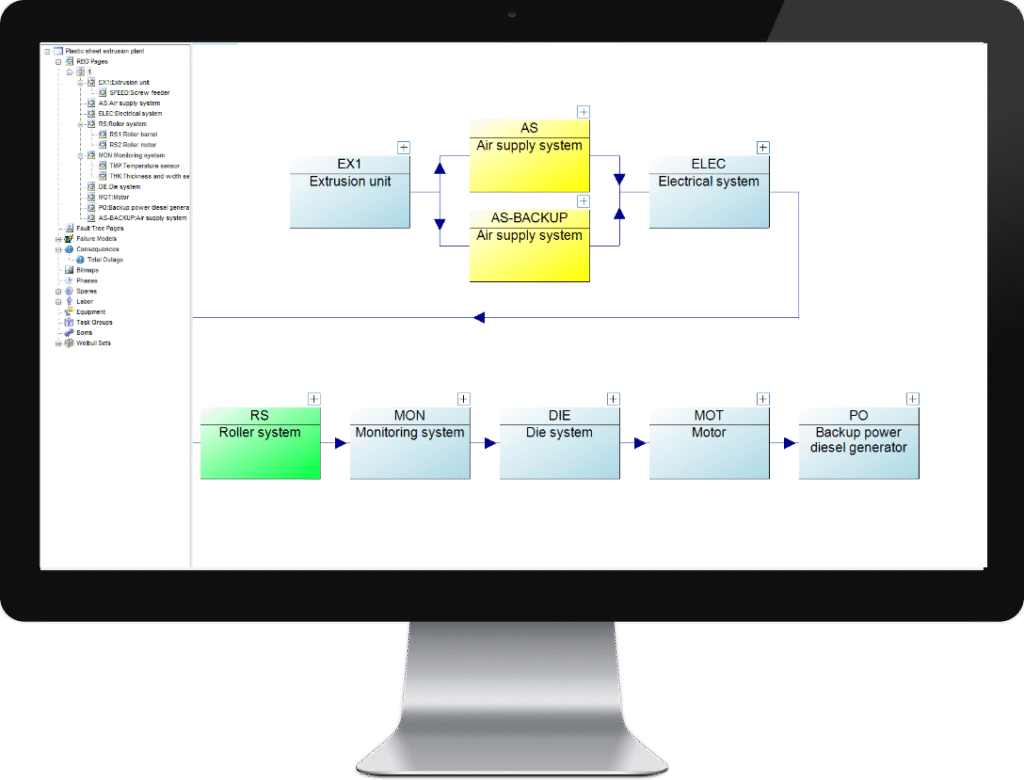

AvSim

The availability and reliability simulator capable of analyzing complex and dependent systems. Download Availability Workbench and dive into our powerful AvSim module.

- Quickly build models using either Fault Trees or RBDs

- Fast and reliable Monte Carlo simulation

- Analysis of historical data using Weibull analysis

- Simulation of multiple-product capacity with target cost penalties

- No limit to the number of hierarchical levels

- Model spare part dependencies and optimization of stock levels

- Handles switching delays and buffering

- Opportunistic maintenance and ‘hold for repair’ modeling

- User-defined rules to re-configure systems during different phases

- Import/export facilities to databases and spreadsheets

- Project lifetime cost comparison

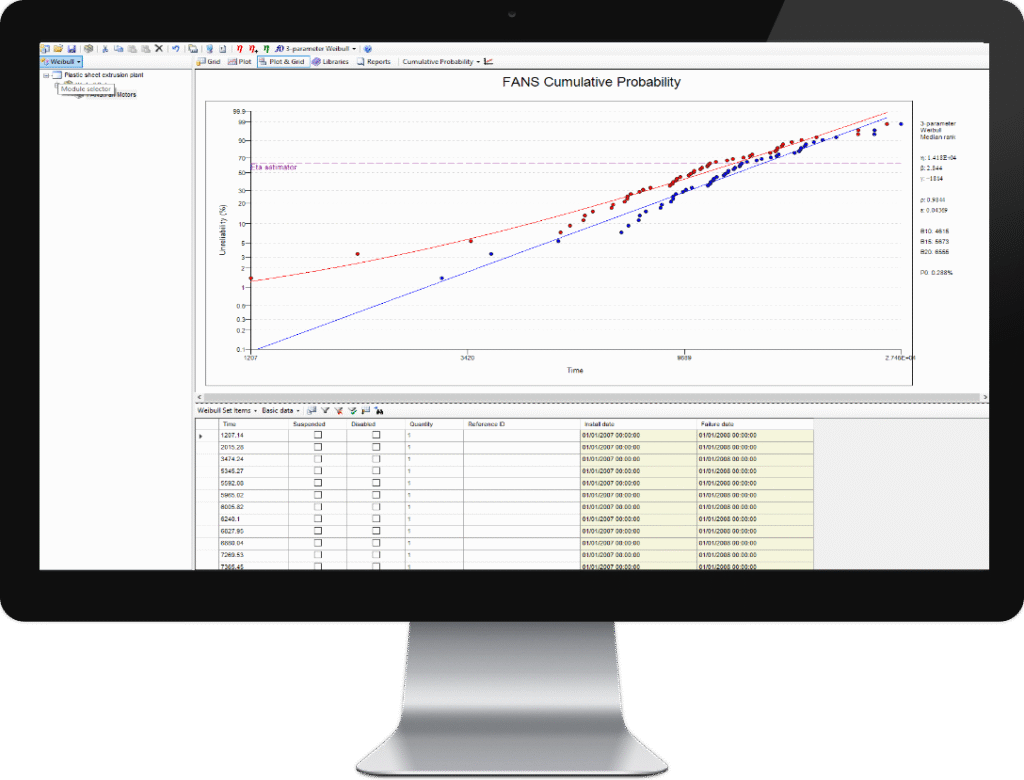

Weibull Analysis

dive into our powerful Weibull module. Analyze historical failure data and produce failure distributions that will be used for system availability simulation and maintenance optimization.

- Multi-phased Weibull distributions

- Lognormal and normal distribution fitting

- Directly link to failure and repair models for system simulations

- Reliability, PDF and failure rate plots

- Connect directly to your SAP or MAXIMO system for data download

- Build Weibull libraries for generic equipment types

- Import/export facilities to databases and spreadsheets

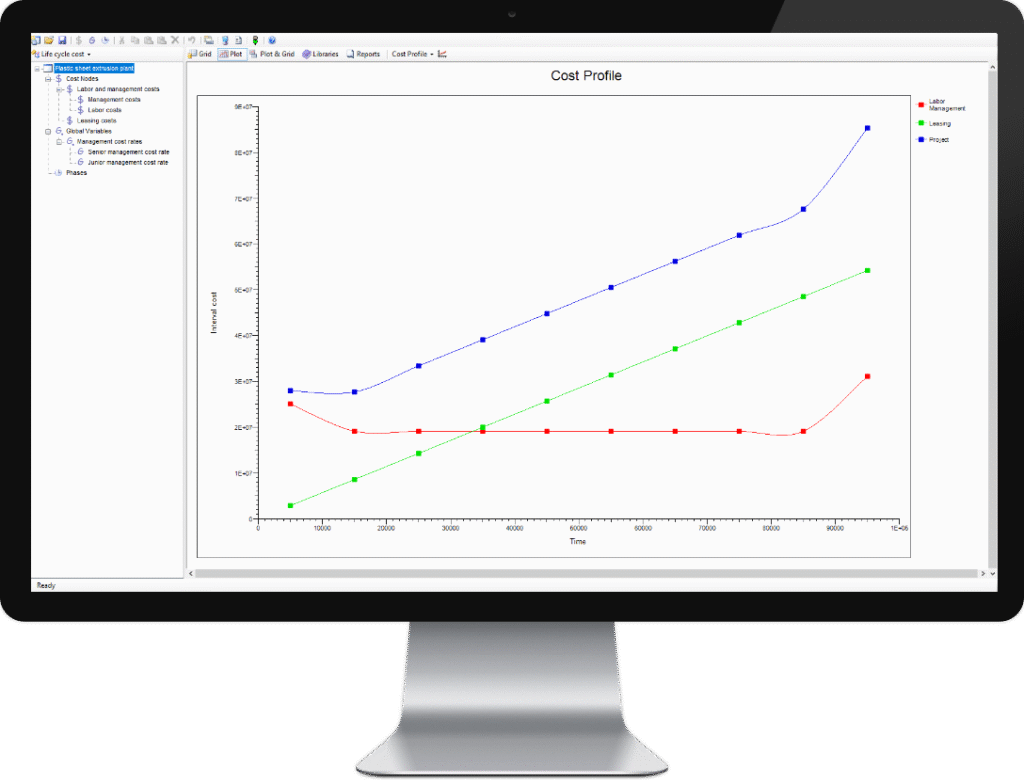

Life Cycle Cost Analysis

In Availability Workbench dive into our powerful LCC module.

- Quickly build hierarchical cost structures

- Define cost equations using intelligent code recognition

- Assign local and global variables

- Link to simulated predicted costs in the AvSim and RCMCost modules

- Apply time and phase dependent models

- Build custom reports using the Report Designer

- Drag and drop custom built library cost structures

- Import/export facilities to databases and spreadsheets

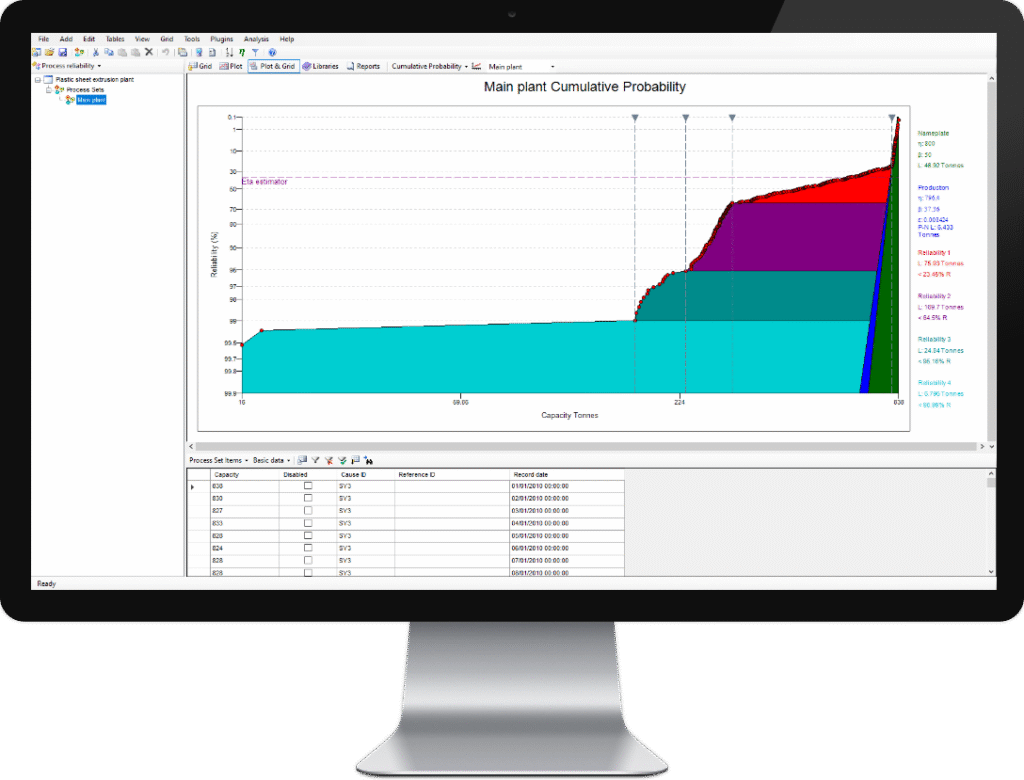

Process Reliability

In Availability Workbench dive into our powerful Process Reliability module.

- Identify systematic and reliability losses by recognizing trends in the production data

- Analyze data using Weibull plots

- Define nameplate production ratings

- Compare production data from different plants

- Distinguish between systematic production losses and reliability losses.

- Automatic calculation of Actual Losses, Production Losses and Reliability Losses

- Import/export facilities to databases and spreadsheets

RCM SAP

Availability Workbench and connect to your SAP® Data.

- Analyze reliability data from your SAP® system

- Visualize performance indicators in plots and reports

- Identify critical equipments and bad performers

- Download existing maintenance plans and failure data

- Optimize maintenance plans in the RCM module

- Upload new or modified plans back into SAP®

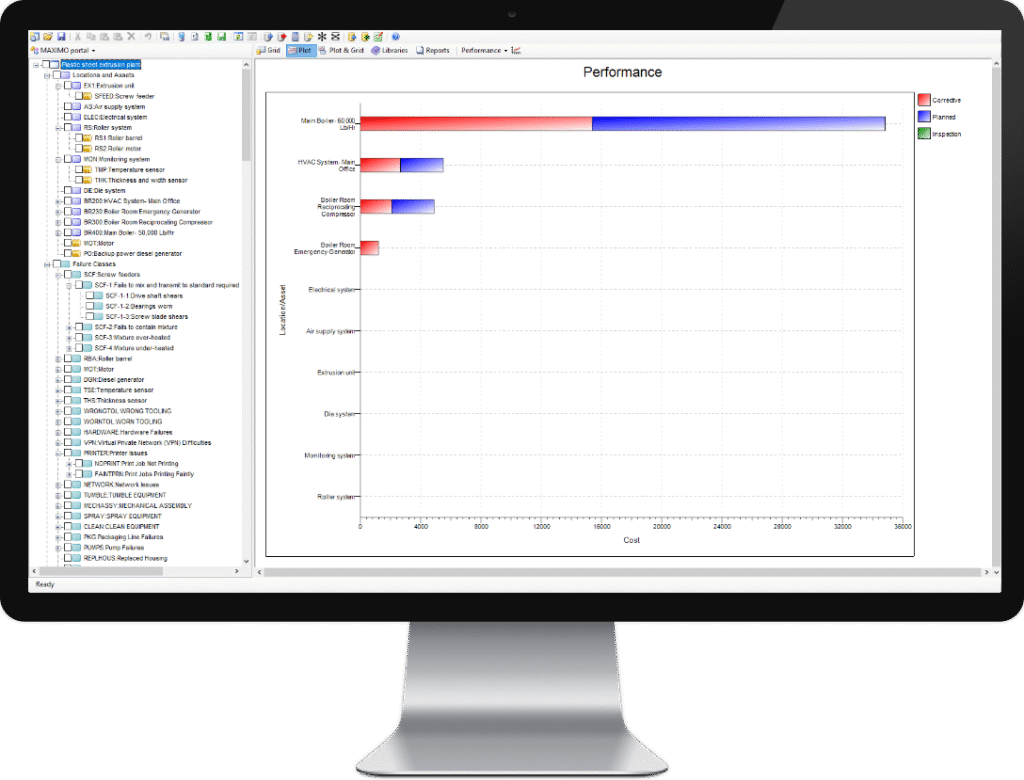

RCM MAXIMO

In Availability Workbench connect to your MAXIMO® data.

- Analyze reliability data from your MAXIMO® system

- Visualize performance indicators in plots and reports

- Identify critical equipments and bad performers

- Download existing job plans and failure data

- Optimize maintenance plans in the RCM module

- Upload new or modified plans back into MAXIMO®

.

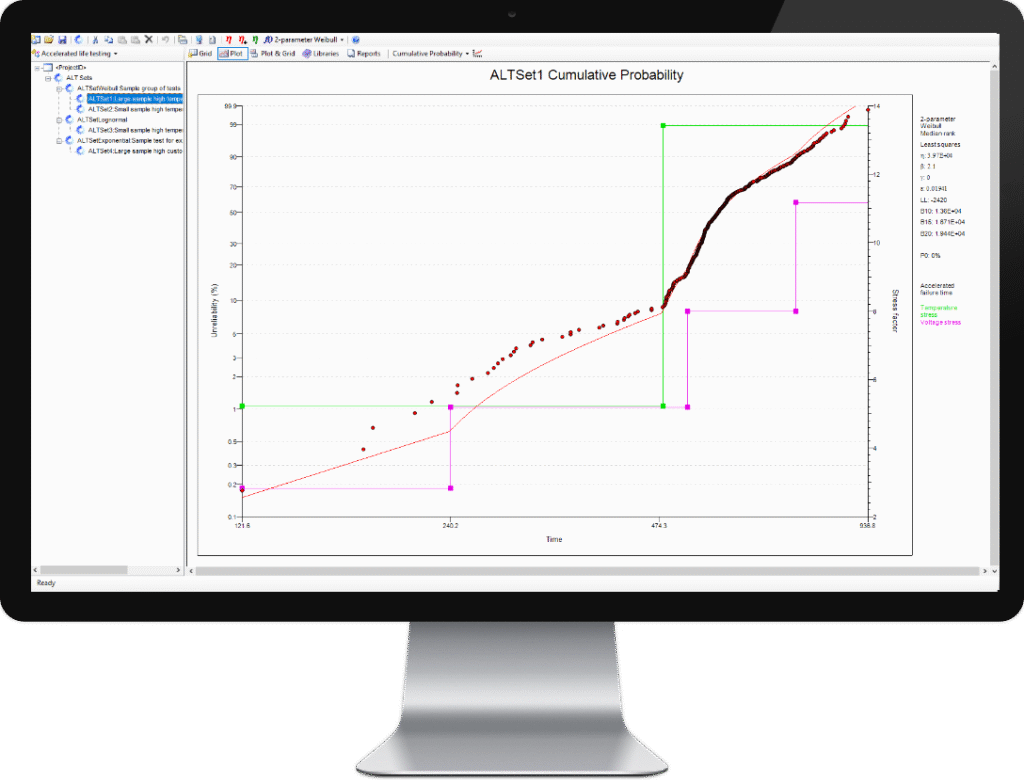

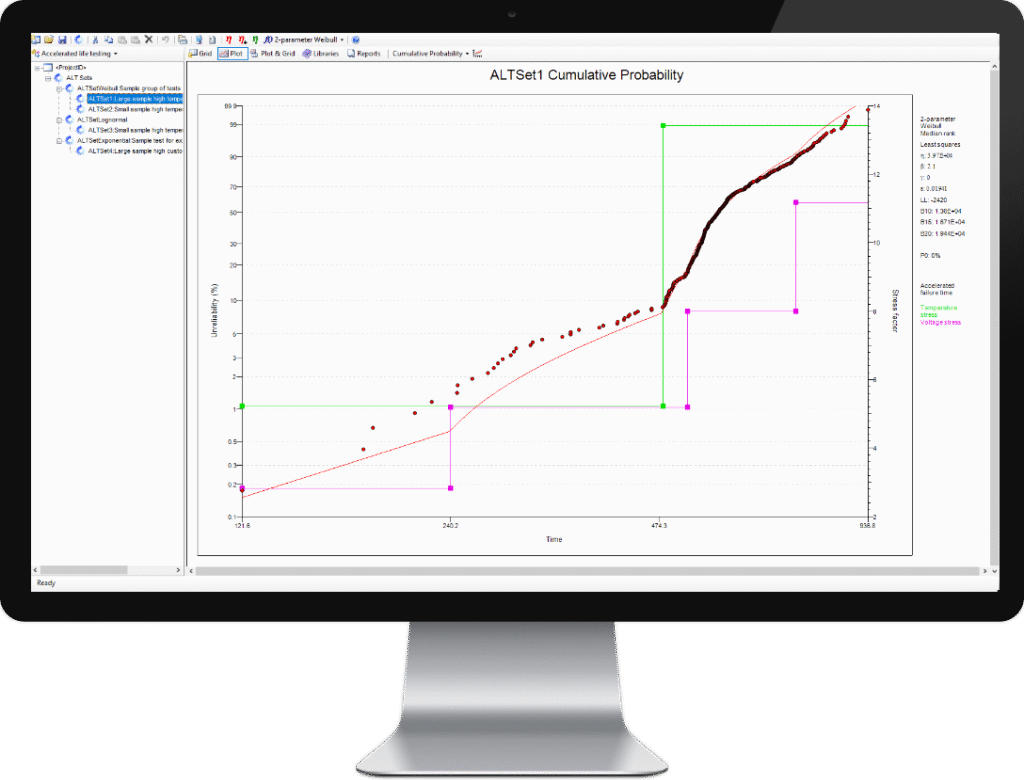

Accelerated Life Testing

In Availability Workbench dive into our powerful ALT module. Analyze accelerated failure data and predict reliability characteristics under normal use conditions.

- proportional hazards or accelerated failure time survival models

- Arrhenius, Eyring, Power Law and custom stress models

- Multi-phased Weibull distributions

- Lognormal and normal distribution fitting

- Reliability, PDF and failure rate plots

- Import/export facilities to databases and spreadsheets

Application Programming Interface

What is the Application Programming Interface?

The Availability Workbench Application Programming Interface (API) enables users to seamlessly link their databases or external applications to Availability Workbench projects. For example, the API may be used to create a custom link between a CMMS database for importing RCM data into a Availability Workbench project. The custom link may then be used to transfer data from the project back to the CMMS database after the RCM analysis has been completed using Availability Workbench.

In summary, the API allows programmers to directly access project data without using the Availability Workbench user interface.

The Availability Workbench API is available by linking to the Availability Workbench Dynamic Link Library (DLL). This is a .NET assembly that runs under the Microsoft .NET Framework Version 4.0. No separate installation is necessary to access the DLL. The DLL is part of the AvailabilityWorkbench.exe file. You will, however, require a DLL license to access the main functionality of the DLL.

In addition to the Availability Workbench DLL you will also require a .NET development tool such as Microsoft’s Visual Studio.

How the Application Programming Interface Works?

The Availability Workbench API provides a DataSet class that may be used to hold project data in memory. A DataSet contains tables, columns and rows. The DataSet constructor automatically constructs all the tables and columns representing the Availability Workbench project schema. However, no rows are added when a DataSet object is created, i.e. a DataSet object contains no data on construction.

A DataSet object may be initially populated with the very minimum of default data for a project by calling the DataSet New method. This method would be called if you are intending to populate a project with data from scratch.

A DataSet object may also be initially populated with data using the DataSet Read method. In this case data is extracted from an existing Availability Workbench project file.

The DataSet class provides methods for writing and reading data to and from the DataSet. Tables and columns in the DataSet are identified by unique string identifiers. These identifiers are listed in the document Availability Workbench DLL Reference Manual.

Why choose Availability Workbench?

Reliability Centered Maintenance

Availability Workbench applies Reliability Centered Maintenance (RCM) procedures for optimizing maintenance strategies based on reliability techniques and encompasses well-known analysis methods such as Failure Mode Effects and Criticality Analysis (FMECA) Read More…

System Availability Simulation

The Availability Simulation (AvSim) module is a powerful system reliability and availability simulator. It is capable of analyzing complex and dependent systems, and allows you to predict capacity and availability as well as identify system weak spots. Read More…

Enterprise Level

Perform maintenance optimization and system availability simulation at an enterprise level using the Isograph Enterprise Database. Read More…

Our Other Products

Reliability Workbench

Reliability and Safety Analysis

AttackTree

Security Analysis and Threat Assessment

NAP

Network Availability Prediction

Hazop

Hazard and Operability Studies.